Pe-PP-Styrene Composite Preparation Plants

WHAT IS PP (POLYPROPYLENE)?

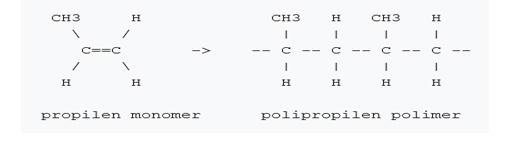

Polypropylene is a thermoplastic polymer with a wide range of applications, from parts used in the automotive industry to textile and food packaging. Polypropylene obtained by polymerizing monomer propylene is extremely resistant to chemical solvents (acids and bases).

History of Polypropylene

The propylene was polymerized for the first time by Giulio Natta and German chemist Karl Rehn in March 1954 and turned into a crystalline isotactic polymer. Thanks to this discovery, the Italian company Motecatini has been continuing its commercial production of isotactic propylene since 1957. Syndiotactic polypropylene was also synthesized for the first time by Natta and her assistants.

What are the Physical Properties of Polypropylene?

Propylene; It is a hard, opaque and solid material. It has a low specific gravity, can float in water. The crystal structure of the most common commercial polypropylene has a level between low density polyethylene (LDPE) and high density polyethylene (HDPE). Young's modulus (elasticity module) is also moderate (It has good dimensional stability in high temperature and humidity conditions.) However, it is less hard than LDPE and much less brittle than HDPE. This allows polypropylene to be used in place of engineering plastics such as ABS.

What are the Chemical Properties of Polypropylene?

Polypropylene shows very good resistance to fatigue. The commercial usage area is quite wide with its low cost. It has very good impact resistance. It has a low coefficient of friction and provides very good electrical insulation. It has good chemical resistance. It is suitable for all thermoplastic processing processes. The melting temperature of polypropylene is between 130 and 171 ° C.

However, despite all its positive features, it also has disadvantages. It has low UV ray resistance and shows high thermal expansion. It is difficult to paint and coat. It has low resistance to external weather conditions. It is open to oxidation. It is flammable and interacts with solvents containing chlorine.

Table 1: Properties of Polypropylene

In general, the technical properties of polypropylene can be listed as follows:

• Low specific gravity,

• High chemical resistance,

• High electrical strength,

• High tensile strength,

• Low abrasion resistance,

• Resistance to low atmospheric effects,

• Can be combined with resources,

• Suitable for food contact.

Polypropylene is the second most important plastic expected to exceed US $ 145 billion in revenue by 2019. Demand for this material has grown approximately 4.4% annually between 2004 and 2012.

What is Polypropylene Used?

It is a thermoplastic polymer with a wide range of usage from the parts used in the automotive industry to textile and food packaging. Polypropylene obtained by polymerizing monomer propylene is extremely resistant to chemical solvents (acids and bases).

Polypropylene (PP) or polypropylene packaging and labeling is a thermoplastic polymer used in many applications such as textiles (eg rope, thermal underwear and carpet), stationery, plastic parts and reusable container types, laboratory equipment, speakers, automotive parts and polymer banknotes. . Polypropylene derived from propylene monomer is a solvent and base and acid resistant and unusually resistant polymer.

Polyproylene can be used in almost every point of our daily life. Kitchen utensils, bathroom utensils, plastic garden furniture, tanks, rotary filters, fan, extractors, bathtubs, clothes hangers, buttons, electrical equipment, cables, threads, floats, laboratory items, stretch films, automotive industry etc.

How is Polypropylene Obtained?

The melt process of polypropylene can be obtained by extrusion and molding. Common extrusion methods include producing meltblown and thread-bound fibers to produce long rolls, and converting them to use in the manufacture of useful products such as face masks, filters, diapers and wet wipes.

The most common forming technique is injection molding, which is used for auto parts such as mug, cutlery, vial, cap, container, household items and battery. Techniques for air pressure molding and injection stretch air pressure molding, which include extrusion and molding processes, are also used.

The specific molecular properties and the possibility of adjusting the level with additives used during its production enables polypropylene to be used in many applications. For example, adding antistatic additives can help polypropylene surfaces withstand dust and dirt. Many painting techniques can be used in polypropylene, such as machining. By holding a surface coating on polypropylene parts, the adhesion capability of printer ink and paints can be improved.

WHAT IS PE (POLYETHYLENE)?

Polyethylene is the most widespread polymer in the world with an annual production of more than 90 million metric tons. After being discovered by accident in 1933, it has become an indispensable part of modern life. The first commercialized product was low density polyethylene (LDPE) polymerized with free radicals. Shortly thereafter, new polymerization chemistries based on the chromium catalyst and Ziegler Natta catalyst expanded the use of the product. LDPE has a wide variety of uses thanks to improved polymer performance based on new catalyst and application technologies. It has become an indispensable part of energy transmission, food packaging, consumer goods, electronics, household goods, industrial storage and transportation industries. In light of the advances in technology, the functionality of polyethylene continued to improve and polyethylene became the area where natural resources, oil and natural gas were used most effectively.

What is Styrene Monomer?

Also called polyester thinner, styrene monomer is a product used for thinning polyester coats and gelcoats. It has a solvent and flammable properties. More than usual styrene monomers impair the property of the resin.

Styrene Monomer and Its Properties

Styrene monomer, which has a solvent property, has its own characteristics. The most important of these is its characteristic smell. The styrene monomer chemical in liquid form has a colorless appearance. When the styrene monomer chemical materials are located in areas that receive heat or light, they become solid from liquid states. The styrene monomers, which reduce the viscosity of the resins, thus provides thinning of the resin and increased fluidity. The resins generally contain 35% styrene. In this case, styrene monomer added more than 10% to thin the resin causes the resin to lose its basic property. Therefore, the saturation point of the styrene monomer is 27 while the boiling point is 145 degrees. The flash point of the styrene monomer with 99% purity is 31.1 degrees. The styrene monomer, which draws attention with its unique features, has a wide usage area.

Usage Areas of Styrene Monomer

The styrene monomer chemical substance, which can be used comfortably in many areas with its advantages, facilitates and thinens the flow properties of the resin. However, styrene monomer contains effective properties in thinning gelcoats. The areas where the styrene monomer, which is formed by connecting molecules of its own type, are used as the basis for creating polymer molecules, can be listed as follows: * Production of polystyrene * Protective paints * Styrene rubber * Unsaturated polyester resin * Styrene acrylic emulsions

English

English