Polyurethane Plants

What is Polyurethane?

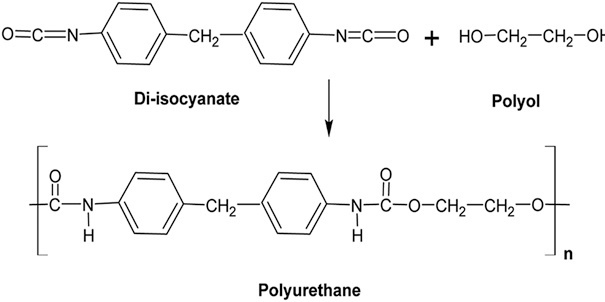

Polyurethane is an important product group in the polymer family. Polyurethane was synthesized for the first time in 1937 by German scientist Otto Bayer and was obtained by reaction of diisocyanate with diol. Later, diols were replaced by larger molecular weight polyols. The polyurethane formed in this way creates a stronger and more flexible structure. 3 main raw materials play an important role in the production of polyurethane foam. These; polyol, isocyanate and water. While some of the diisocyanate polymerizes with polyol, a small part of it reacts with water to form a porous polyurethane structure. Catalyst, stabilizer and other auxiliary agents are used to support the chemical reaction. Additionally; Additives such as paint and flame retardant can also be added to the formulation, if desired, to obtain specific properties. At the end of the curing time (24-72 hours), a flexible and solid polymer structure is formed. Two important measurements about sponge are density (density) and hardness. Quality is directly related to density. High density means high quality. Hardness has no effect on quality. High-quality sponge can feel soft and low-quality sponge can feel hard.

All sponges lose hardness with use. Better quality sponges lose their hardness slower. Color has no effect on sponge in terms of quality and performance. The natural color of the sponge is white. Color is only used to distinguish different quality sponges more easily.

Polyurethane Properties - Attributes

Polyurethane Density: Density, ie density, is defined as the weight per unit volume and measured in kg / m3 or gr / dm3. Flexible Sponge is one of the most important properties of Polyurethane and it affects the durability and support strength. High density products retain their original properties longer.

Polyurethane Hardness: Flexible Sponge Hardness in Polyurethane is a measurement of the surface touch or feel of the sponge. Support is the ability of the sponge to push back against the weight. The stiffness and support both affect the comfort of the sponge. The hardness or softness of the sponge is not directly related to density. Many times, incorrectly, high density sponges are thought to be harder. However, hardness is completely independent of density. Hardness is measured by the force expended to compress a sponge sample to 40% of its original height.

Scope of application

Polyurethane (PU) sector, which is one of the sub-branches of the plastic industry, started to be mentioned as one of the sectors of the future with the introduction of polyurethane in every area of life.

English

English